Fibreglass Sheet Revolutionises Caravan Flooring Design

Weight reduction is a key trend driving caravan construction. Technological advancements and new methods using alternative materials like extruded polystyrene XPS foam and fibreglass sheet has allowed manufacturers to achieve significant reductions in weight while maintaining a high level of durability and overall quality.

Lighter floors are especially important for reducing weight in caravan design. However, it’s challenging to find an approach that reduces weight significantly while maintaining the required stability and strength to support the structure of the vehicle and weight of appliances, occupants and cargo. It’s also important to find materials that improve resistance to damp and moisture to prevent mould and swelling, and optimise thermal insulation in caravan flooring.

Replacing Plywood with Fibreglass Sheet

The traditional material used for caravan flooring is wood, which is heavy, absorbs moisture and is susceptible to mould. This can now be replaced by a lightweight laminated sandwich structure. Caravan design engineers and manufacturers can now take completely new approaches to floor design by using fibreglass sheets, which are now an essential element in sandwich floor structures.

Traditionally, a single PVC layer would be affixed to a plywood flooring surface. Replacing that with fibreglass sheet offers countless benefits. GRP is waterproof, cost-effective, easy to install, resistant to scratches, corrosion and impacts, easy to repair and has a low thermal expansion coefficient. GRP can be bonded with PVC, allowing for a seamless, aesthetically pleasing finish that means no lifting, tearing or sagging.

A Perfect Bond Between the GRP and Décor PVC Sheet

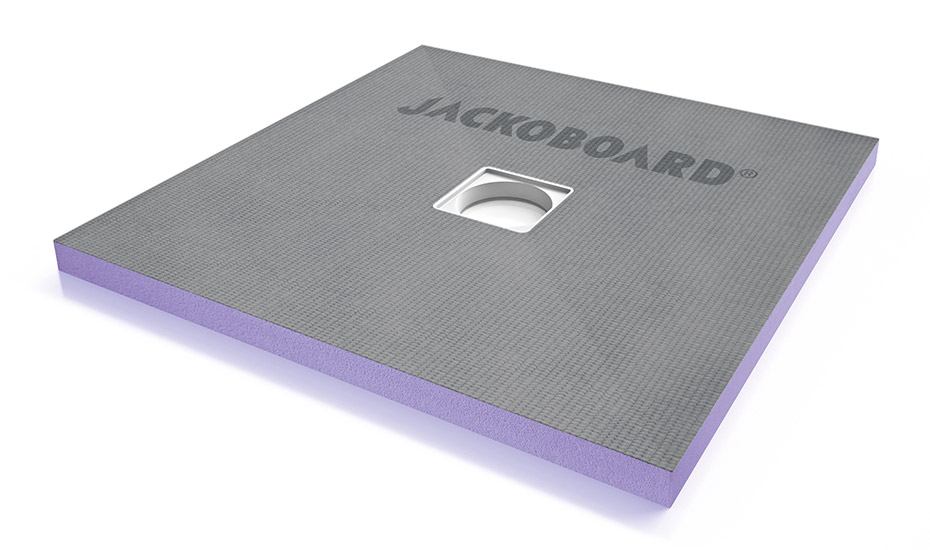

Elyplan® Design fibreglass sheets are characterised by the bonding of Décor PVC directly onto the fibreglass sheet during the production process. This ensures maximum strength and eliminates the necessity of using adhesives to fit the PVC because a perfect bond already forms between the two substrates. To create sandwich panel flooring, the manufacturer can simply laminate the material to a core foam structure such as XPS foam.

The completed composite sandwich panel is incredibly beneficial when used for caravan flooring, in terms of offering a high standard of insulation performance and water resistance as well as being able to withstand the compression, tension, bending and shear forces associated with vehicle movements. The outer composite laminate absorbs compressive and tensile forces from loading, while the XPS foam core layer absorbs shear and dynamic forces created by vibration and torsional stress while driving.

Brianza Plastica’s Elyplan® Design Flooring Laminate

Driven by industry demand, Brianza Plastica has developed Elyplan® Design, a composite laminate of excellent quality that can be used to manufacture beautiful, highly durable caravan floors. This ready-to-use composite element is available in a wide range of colours and finishes, serving as an excellent alternative to plywood. This composite laminate combines the advantages of a continuous product with a wide range of different aesthetic finishes.

Elyplan® Design Floor rolls come in thicknesses of 1.3mm and 1.5mm and widths of up to 3m. Sheets are also available on demand. Elyplan® Design Floor is completely odour-free thanks to the innovative “Styrene Free” resin used to manufacture the product. It offers many advantages, from a perfect bonding with all standard adhesives to improved mechanical performances.

Lightweight Materials Improve Fuel Efficiency

By replacing a heavier floor with a lightweight composite sandwich panel floor, the potential savings in fuel costs are massive. Every kilo saved in the construction of any vehicle, whether a caravan or motorhome, results in less energy needed over its lifetime. Composite floors are more eco-friendly as a result and offer huge cost savings for the consumer. A lighter vehicle means less energy is used every day. Over a typical 25 year lifetime of a vehicle, the energy savings are significant.

The material-to-material bond between the fibreglass sheet and Décor PVC means there is no need for the extra weight of the adhesive bondline. This high level of quality and reliability in demanding applications make Elyplan® Design Floor ideal for smart lightweight construction. This integral design enables manufacturers to save on raw materials and streamline the production process during further processing.

Brianza Plastica – The Experts in Fibreglass Sheet

Outstanding quality, lightness, strength, aesthetic appeal and a variety of finishes allow the Elycold® and Elyplan® fibreglass sheets by Brianza Plastica to be used widely in the field of recreational vehicles (campers and caravans) for the construction of walls, anti-hail roofs, floors and interior coverings. The special protective gel coat protects against UV rays and yellowing, preserving quality and appearance over time.

Elyplan® Design Floor Available from Liner

Italian company Brianza Plastica is one of the leading European manufacturers of fibreglass sheet for vehicle production. Brianza Plastica employs both discontinuous cold-lamination and continuous hot-lamination processes for maximum production flexibility so they can reliably meet the unique needs of manufacturers operating in a variety of industries including the production of caravans and motorhomes.

At Liner, we’re dedicated to supplying manufacturers with the highest quality materials from leading brands like Brianza Plastica. Contact us today for a quote, product sample, consultation or for more information about Brianza Plastica products.

Related Questions

Are fibreglass laminates waterproof?

High quality fibreglass sheets like Brianza Plastica’s Elyplan® Design Floor repel condensation and prevent moisture related issues inside the caravan, ensuring the vehicle lasts longer. Ventilation built into the design of the caravan is also crucial for preventing condensation inside the caravan.

Are fibreglass laminates better than aluminium sheets?

Fibreglass is more versatile, has a lower thermal expansion coefficient and much better impact resistance for things like hail.

What is a composite sandwich panel?

Composite sandwich panels commonly consist of two facings and a core. The core usually consists of a rigid plastic foam, the most suitable being extruded polystyrene XPS and polyethylene terephthalate PET foams while the outer facings are ideally made of a quality fibreglass sheet like Elyplan® Design Floor. Sandwich panels are notorious for their impressive strength-to-weight ratio, making them ideal for caravan floors.