Making your Production Process independent from Temperature Fluctuation

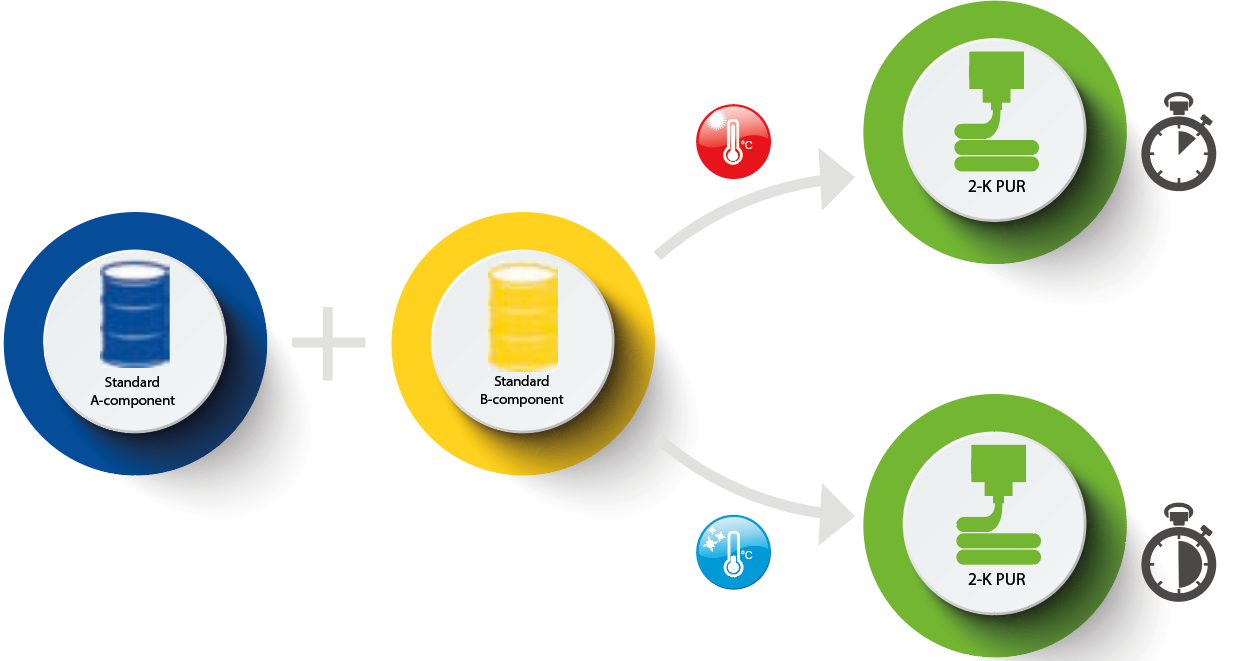

If we only considered the reactivity it would be easy to change the base reactivity by switching to another potlife version. This would mean you need to store several A-components with different

potlifes and chose the right one depending on the temperature (see graphic 1). From a logistic point of view this is a nightmare and nearly impossible to handle in practice.

In order to get the problem under control, we alternatively offer our customers a 3-K system rather than a 2-K version of our polyurethane products. Therefore the customer will premix two different A-components – one with a long and the other one with a short potlife in variable mix ratios depending on the temperature. Afterwards the premix will be mixed classically with the Isocyanate to the final product (see graphic 2).

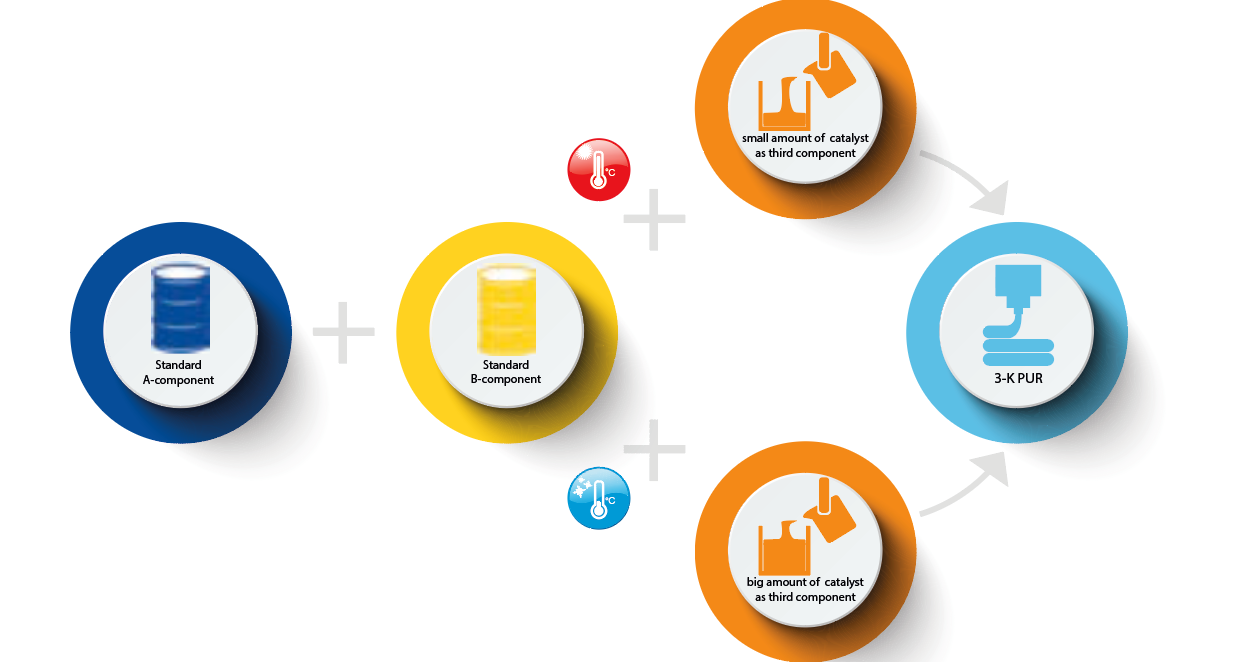

An alternative to the previously described procedure is to work with

three different components: using the A-component with a long potlife, mixing it with the standard B-component and influencing reactivity by adding a third component as a catalyst to the system (see graphic 3). This solution has been proven in practice for the assembly bonding

of the front wall of a reefer trailer. We provided the customer with

a graph showing exactly how much catalyst was needed to add depending on the temperatures. After slight additional adjustments we finally were able to fulfill the customers’ requirement to eliminate the temperature impact on the reactivity of the product in use.

Even at constant temperatures, this 3-K system benefits the production process as it allows the process cycle times to be individually adjusted. This means, for example, that small (short processing time) and also large sandwich parts (long processing time) can be produced together in one work shift.